This hands-on Hobart Handler 140 review features a welder I purchased three years ago.

My research found this MIG welder popular with DIY’ers tackling the same light welding tasks I do: home and business maintenance repairs, auto bodywork and just creating stuff in the garage.

I like that it has an excellent reputation going back years. It’s best known as a reliable, no-frills, simple to use beginner welder.

And with a proven transformer-style power supply, they build the Hobart 140 to last — in the USA.

It’s still assembled in Troy, Ohio by Hobart Welding Products, a century-old welding manufacturer. They design products specifically for consumer DIY and small business users.

While sharing a few components as sister companies, Hobart and Miller Electric produce welders in different plants. Miller builds its prosumer and commercial machines in Appleton, Wisconsin.

Jump to:

- A long-time favorite MIG welder of hobbyists and homeowners

- Dependable, straightforward operation is ideal for learning to weld

- Rugged build designed for years of trouble-free welding

Pros

- Just two knobs and a good settings chart make weld setup simple

- Easy change 3-groove drive roller (quick, no tools)

- Plugs into standard 115 volt power outlets

- Welds aluminum without an expensive spool gun

- Warranty covers expensive repairs for 5 years

Cons

- No spool gun option

- Regulator not approved for CO2 shielding gas

- Work clamp is small; not heavy-duty

- Gasless nozzle is not included

- Power cord is only 5 ft.

What’s included with the Hobart 140 MIG welder kit #500559?

- 10 ft. MIG gun & cable

- 10 ft. work cable with clamp

- Power cord with plug

- Built-in gas solenoid valve

- Dual gauge gas regulator (for 100% Argon or Argon blends) with gas hose

- .030 in. contact tips

- Quick Select™ drive roll for .024 in. and .030/.035 in. solid wire, and .030/.035 in. flux cored wire

- Spool hub assembly (handles 4-inch and 8-inch wire spools)

- Sample spool of .030 in. self-shielding flux-cored wire

- Material thickness gauge

- Owners Manual/Welding Guide

What should you know before buying the Hobart Handler 140?

Power requirements

While this Hobart welder will operate from any 115-volt outlet, to achieve maximum performance (rated weld thickness) you’ll need a dedicated 20-amp circuit. If you’re lucky, your garage has one. But most, like mine, are 15 amp.

Now, the Hobart 140 welder will run on 15A, but with reduced output and duty cycles. You’ll be okay with light-gauge materials, but don’t expect miracles on 1/4 inch steel.

It’s a highly rated welder with few complaints. It wouldn’t surprise me if 75% of the performance criticisms result from using an inadequate power source.

On thick material, the arc performance is absolutely better running on the dedicated 20A outlet at my business. On 15A power, I get a nice, smooth welding arc as long as I don’t push the upper limits.

Flux Core vs. MIG

With the included sample spool of flux core wire, you won’t need gas to test your new MIG welder. The Hobart Handler 140 is ready to weld right out of the box.

What’s missing is a gasless nozzle like this. Tighter fitting than a MIG nozzle, it protects the gas ports from getting covered by spatter. This can block the shielding gas, causing poor quality MIG welds.

This Hobart 140 welder includes an internal gas valve and an external regulator and hose. You get everything needed to MIG weld except the solid wire and shielding gas.

Depending on what welding cylinder size you choose, you can spend up to several hundred dollars to begin MIG welding. MIG will give you cleaner welds and more control on thin metal, but at a cost.

I weld a lot with flux core—because I can weld a lot with it. I like the convenience of gasless welding. And this Hobart 140 is a great flux core welder.

If you mostly work outdoors, or if weld appearance isn’t a priority—lawn and garden equipment, fences, etc. — you may want to consider a flux core-only welder.

You can save $100s and get an easier-to-carry machine with this welder.

Material Thickness

140-amp MIG welders running on 115V power are best used for thin sheet metal and steel plate up to 3/16-in. You’ll need multiple passes and a good 20-amp electrical circuit to weld thicker materials.

For welding 1/4-inch and thicker, a 230V welder is best. If you like the 140, the Hobart 210 MVP runs on both 115V/230V power.

Hobart Handler 140 Rated Welding Capabilities (single-pass)

- Flux-core steel: 18 gauge to 3/16 inch

- MIG steel: 24 gauge to 3/16 inch

- MIG stainless steel: 18 gauge to 10 gauge

- MIG aluminum: 16 gauge to 12 gauge

Aluminum Welding

Most MIG welders in this category require an expensive accessory to weld aluminum. This Hobart MIG welder is unique because it can weld 16- to 12-gauge aluminum out of the box.

See the settings I used to MIG weld 1/8-inch aluminum without a spool gun.

Unlike this machine, the Lincoln 140 is capable of spool-gun welding aluminum. But even it’s limited to thin 22- to 10-gauge material.

For heavier aluminum work, you’ll want the power of a 230V machine. Again, the Hobart 210 MVP (kit with spoolgun) is a great choice.

Hobart Handler 140 Review of Top Features

Simple to Use

I haven’t come across a better owner’s manual for any welder. It’s complete, well-written, and illustrated. Get it here from Hobart.

Assembly is a breeze—you can have the Hobart 140 welder unpacked and ready for flux core welding in under 15 minutes. Just a little longer if you’re using shielding gas.

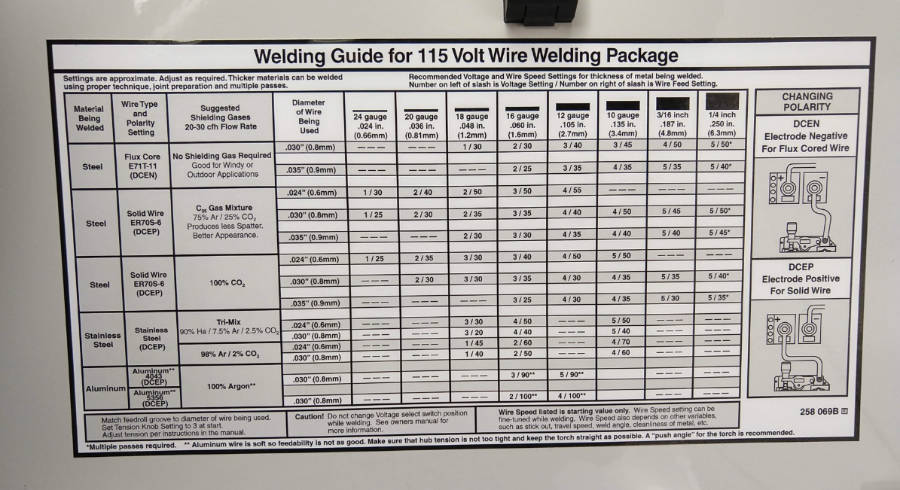

Even a beginner can quickly set up a weld using the detailed welding guide chart mounted inside the access panel. Hobart even includes a handy metal thickness gauge.

After my initial read, I like that I don’t have to go back to the manual when I use this Hobart welder, even when months have gone by.

The control panel is uncluttered with just two control knobs, a power switch, and an over-temperature indicator lamp. I can easily make adjustments without removing my gloves.

The WFS (wire feed speed) control, marked 10 to 100 for reference, is infinitely adjustable between 40 and 700 ipm (inches per minute). While I found the chart settings accurate when on good power, ideal wire speed varies with input power, stick out, travel speed, weld angle, cleanliness of metal, etc.

Are you wondering why the top WFS is 200 ipm more than most 140-amp welders? It’s a big part of what helps the Hobart Handler to weld aluminum. More on this, later.

A 5-position (aka stepped, fixed, or tapped) control sets your voltage. While infinite control is handy for fine-tuning, 5 heat settings with an output range of 25 to 140 amps are plenty. Remember, you have a large WFS range available for dialing in your arc when needed.

Superior Build Quality

My first hands-on impression of the Hobart 140 was: “This is not a toy!”

Inexpensive knock-off welders flood the market. Some of them even work pretty well, but the build quality won’t thrill you.

The Hobart Handler is a no-frills welding machine, but there’s no doubt it’s built from quality components.

With metal panels and frame, it’s sturdy. There’s some plastic trim, but even that is thick.

Yes, this welder is heavy. It weighed 54 pounds with the power cord and work cable. The gun and cable add 3.7 pounds. So, nearly 58 pounds before adding wire.

Because a few buyers of the Hobart 140 reported a disconnected internal gas hose, I wanted to check this one. Yes, I took the machine apart before using it (I just had to).

I was happy to find the gas hose was secure (even without a clamp) and even happier to see the internals laid out so nicely! Troubleshooting and repair access is good, and there’s even an electrical diagram mounted to the cover.

Gun and Cables

The gun is comfortable, and the switch operates well with gloves.

A quality covering makes both cables easy to handle. They stay flexible down to at least 30 degrees and don’t take on a set when coiled. However, the 5-foot power cord became stiff below 50 degrees.

The 10-foot torch cable is just long enough to reach around most projects. But I think 15 feet is the ideal length.

The 6-gauge work cable is also 10 feet long, but they skimped on the work clamp. When compared to a Lincoln 140, the Hobart clamp is smaller and lacks a bonding cable. Learn more in this Hobart 140 vs Lincoln 140 comparison.

I always make sure the top jaw has good contact on the work to avoid an erratic arc and poor welds. Fortunately, replacement with a good clamp is a cheap and easy fix.

Wire Feed Drive

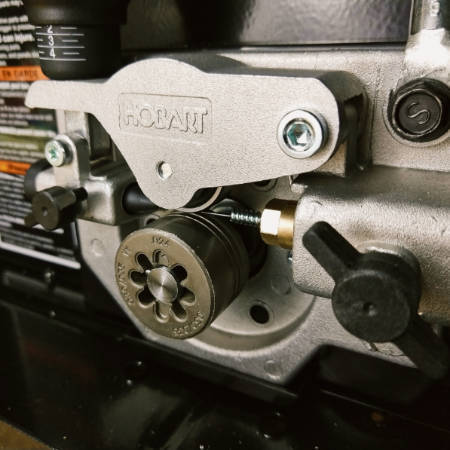

I should really apologize for calling this a “no-frills” welding machine—the drive system is kind of special.

First, as we know, it’s fast—700 ipm fast.

Second, it’s good at feeding soft flux core wire. It even runs ultra-soft and flexible aluminum wire at high speed through its 10-foot cable and gun without birdnesting, crushing, or jamming.

If the drive isn’t fast and reliable, you can’t weld aluminum. That’s why it’s rare for a manufacturer to recommend it.

Third, it’s equipped with the Quick Select system. It features a user-friendly triple-groove drive roller. Changes are fast: push-in, twist to align pin with type and diameter, and then release. All three grooves are available without removing the roller.

I like not having to store (lose) extra drive rollers.

You get two smooth grooves for .024” solid wire and .030/.035” solid or flux core. The extra .030/.035” knurled groove provides a good grip on the soft wire using lighter roller tension settings. This avoids feed issues caused by squeezing or deforming.

The calibrated feed tension control allows precise pressure control to prevent slippage or crushing.

Tip: Start with a setting of 1.5 for flux-core or aluminum and 2 for solid MIG.

Finally, it’s built to last with a housing of heavy cast-aluminum.

Overload Protection

Hobart designed three levels of protection into this 140-amp welder:

Drive Motor – A separate auto-resetting overload circuit protects the drive motor.

Output Overload – A manually resettable circuit breaker to protect the welder from exceeding maximum output. Max Open Circuit Voltage (OCV): 28 VDC

Thermal Protection – An automatic thermostat protects the power transformer from overheating when you exceed the duty cycle. It prevents further welding until the fan cools the unit. A panel light remains on while the machine is in thermal overload protection mode and turns off when ready to weld.

Duty Cycle

The rated duty cycle rating is 20%@90A 18.5 VDC with 115V, 20A input. This means that when producing 90 amps of output, it should operate for a maximum of 2 minutes (20%), and rest (cool down) for 8 minutes during a ten-minute period.

This rating is about 2/3 power for a 140-amp welder. Duty cycles vary inversely with the output power. Increasing the output will reduce the duty cycle while decreasing output will increase the duty cycle.

In reality, few hobbyists have duty cycle issues when adequate power is supplied to the welder. This means running on a 20-amp circuit without an extension cord.

Gas Regulator

You’ll get a nice Miller-branded gas regulator and hose with the kit. It’s brass, with dual gauges to monitor flow rate and tank pressure. It works with 100% Argon and Argon blends, such as C25 MIG-mix, but is not compatible with 100% C02.

Warranty

Made in the USA and a long warranty?

Yup, the Hobart 5/3/1 warranty features parts and labor coverage to five years on the power source (transformer), three years on the drive system, control boards, and regulator. They cover the MIG gun, contactors, and relays for one year (90 days for industrial use).

The Bottom Line

My Hobart Handler 140 MIG welder has lived up to its reputation—and my expectations.

It’s been trouble-free for three years, and I enjoy welding with it. I would definitely buy this Hobart 140 again.

As long as you’re okay with its limited aluminum capability, I can’t recommend a better affordable welder with the Hobart 140’s quality of build, ease of use, and great warranty.

Lately, Amazon’s pricing and availability is good on this welder.

But if this machine is not a fit for you, here are the best 110V MIG welders.