Hands-down, my auto-darkening helmet is my favorite piece of welding safety equipment. I appreciate the technology that not only makes a product safer but more comfortable and enjoyable to use.

Adjustable auto-darkening welding helmets protect your eyes from radiation and bright welding arcs with lens coatings and electronic shades from DIN 3 to a super dark DIN 14.

A light shade setting of number 3 or 4 provides enough visibility to position your MIG gun without having to lift your mask, but what shade lens for MIG welding?

What shade lens for MIG welding?

“As a rule of thumb, start with a shade that is too dark to see the weld zone. Then, go to a lighter shade which gives a sufficient view of the weld zone without going below the minimum.”

OSHA Fact Sheet No. 3499

Recommended Filter Lenses for Protection during Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW)

|

Arc Current |

OSHA Shade Number Minimum | ANSI & AWS Shade Number |

|---|---|---|

|

UNDER 60A | 7 |

– |

|

60-160A | 10 |

11 |

|

160-250A | 10 |

12 |

|

250-500A |

10 |

14 |

According to OSHA’s Fact Sheet, MIG welding (GMAW) or flux-cored welding (FCAW) using currents of 60 to 500 amps requires a minimum lens shade level of a DIN number 10.

Both ANSI and AWS are more cautious, recommending a shade number 11 for welding at 60-160 amps, a number 12 for 160-250 amps, and a number 14 for 250-500 amps.

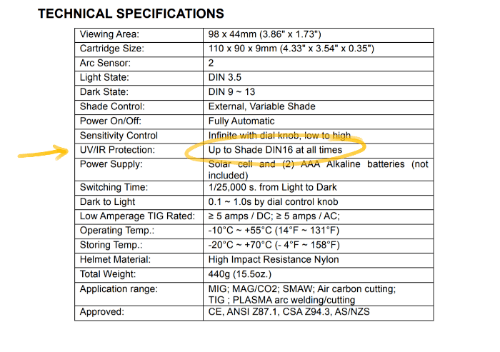

You may not know that most welding helmets with auto-darkening filters (ADF) provide full, or close to full, protection from eye-damaging ultraviolet (UV) and infrared (IR) radiation at all times, even while in the passive light state.

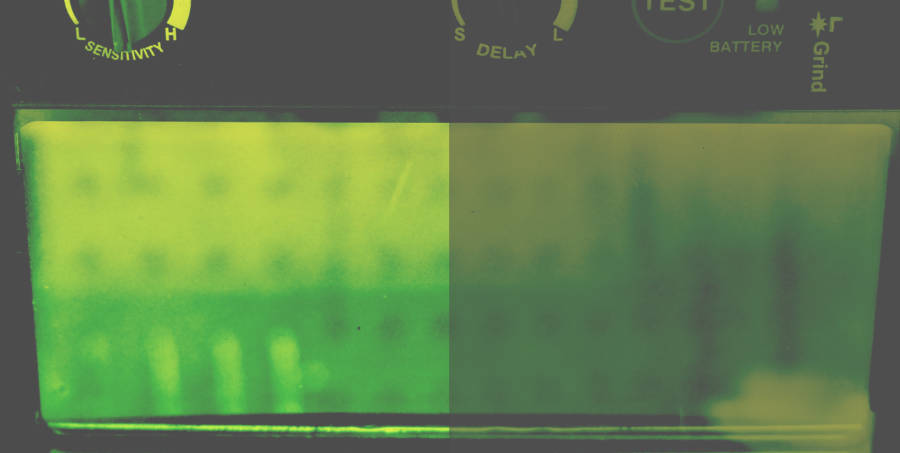

I found this in my helmet manual:

…and this from another helmet manufacturer:

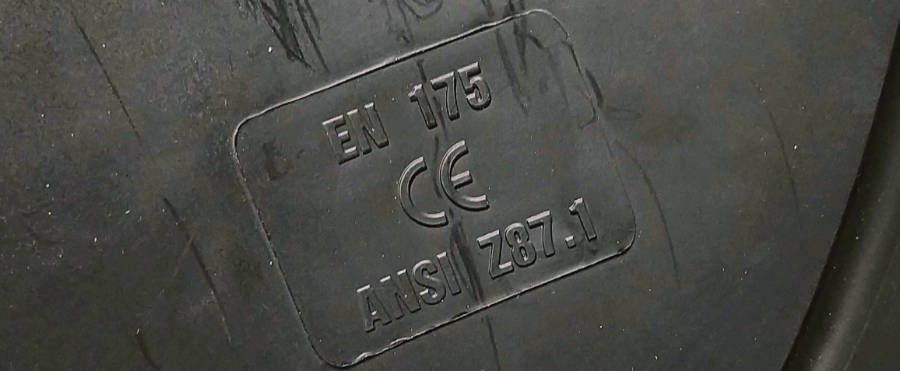

“Has permanent protection (Shade 12 equivalent) against harmful UV- and IR- radiation, regardless of whether the filter is in the light or dark state or whether the auto-darkening function is operational.”

—3M Speedglas 100 Datasheet

Instead of relying on dark state shade settings to block eye-damaging radiation, auto-darkening helmet manufacturers use special lens coatings to filter out the rays.

So, if the helmet battery dies, you leave the mask in grind mode (so easy to do!), or the ADF fails to darken for any reason, the lens still protects your eyes from damaging UV or IR rays.

You may experience temporary spots in your vision from the brightness, but you won’t suffer permanent eye damage or painful conjunctivitis known as “welders’ eye” or “arc flash.”

To protect your eyes, look for helmets meeting ANSI Z87.1 standards and review the manufacturer’s technical datasheets for a helmet’s permanent shade protection level.

What does the welding lens shade number mean?

The DIN rating is a German industrial standard used to classify light filtering levels. As the DIN number increases, the lenses become darker and block more light.

Most auto-darkening lenses have a passive base level of DIN 3 or 4. This light state is bright enough so you can see to set up your work without having to lift your hood.

And it allows you to see well enough to operate your grinder—provided your helmet has a grind mode to prevent grinding sparks from triggering the darkened state.

Popular Welding Helmets

A DIN shade 3 level allows around 14% of visible light through the lens, while DIN 4 is three times darker, allowing only 5% light transmission. This is a significant difference that you should consider if you don’t always work in a brightly-lit area.

Here are some of the best work lights for welding use.

My helmet has a base shade of DIN 3.5 (10%). As a hobbyist welder most often working in the corner of my garage, I think anything darker would be too dark for my comfortable use.

By comparison, blocking the brighter-than-the-sun welding arc, shade 9 allows just 0.037% light transmission, and shade 13 only 0.00072% (blocking 99.99928% of light!).

Here’s a brief video showing what you can see in the light state compared to the darkened mode:

How to adjust your auto-darkening shade lens?

If you use an ADF helmet having a permanent shade rating higher than the capacity of your welder—meaning the lens coatings will block all the UV and IR your welder generates—you’re free to choose a setting based on your comfort.

An ideal setting is just light enough so you can see what you need to see but dark enough to prevent eye fatigue. If you see spots in your vision after a weld, it’s time to choose a darker shade setting.

My personal preference runs closer to the darker shade settings in the ANSI and AWS recommendations. The reason is likely my light-colored eyes. As everyone is different, your actual setting will depend on your working environment and personal preferences for comfort and visibility.

How to test your auto-darkening shade lens

Many better auto-darkening welding shade elements have a self-test button to show you that the ADF in your helmet is working. But remember, this test only determines that there is battery power and the ADF can work, it doesn’t prove that it will work when you strike an arc.

There is another quick and easy method to test your lens operation, including the sensors, for troubleshooting purposes or your peace of mind. The helmet sensors trigger off IR from the welding arc. An ordinary television remote control emits an IR signal that will also trigger the helmet’s sensors.

This handy trick can also test how well the sensors pick up signals from side-to-side, or above and below your mask. Good information to know when working around other welders.

What are symptoms of “Arc Eye”?

“Certain types of UV radiation can produce an injury to the surface and mucous membrane (conjunctiva) of the eye called “arc eye,” “welders’ eye” or “arc flash.” These names are common names for “conjunctivitis” – an inflammation of the mucous membrane of the front of the eye. The symptoms include:

- pain – ranging from a mild feeling of pressure in the eyes to intense pain in severe instances

- tearing and reddening of the eye and membranes around the eye (bloodshot)

- sensation of “sand in the eye”

- abnormal sensitivity to light

- inability to look at light sources (photophobia)

The amount of time required to cause these effects depends on several factors such as the intensity of the radiation, the distance from the welding arc, the angle at which the radiation enters the eye, and type of eye protection that the welder or bystander is using. However, exposure to just a few seconds of intense UV light can cause arc eye. These symptoms may not be felt until several hours after exposure.”

Canadian Centre for Occupational Health & Safety

Need a good, reliable helmet for hobby MIG welding?

I still use my first auto-darkening helmet bought from Northern Tool in 2010. Before the Klutch branding of Northern’s welding gear, it’s a Northern Industrial Welding Model 19056. I think it was $60 at the time.

I consider this one of the best welding purchases I’ve made. As a MIG welding beginner, upgrading from a no-frills, fixed-shade mask to a much more convenient to use auto-darkening helmet was a real treat for me. I felt safer, more comfortable, and much more able to focus on learning to weld.

Related reading: Best Beginner Welding Helmet: 11 Things You Need

What I like about my helmet:

- Easy to use and reliable

- Solar and AAA battery powered (original batteries lasted seven years).

- It’s light and comfortable to wear.

- Room to wear safety glasses under the mask for even more protection.

- Grind mode so sparks won’t darken the shade.

- Reasonable price

There is one problem I have with my helmet

I often use my helmet’s grind function. But the switch is located inside the helmet, making it difficult to operate without removing the mask or taking off a glove.

If I were to replace this helmet, I’d look for one with an external grind mode switch—like on this helmet—that I could operate wearing gloves without disturbing other nearby settings.

Before you go

Sure, welding as a hobby has some risks. There’s live electricity, red-hot pieces of metal—sometimes flying through the air towards your face—and brighter-than-the-sun arcs. What could go wrong?

But in truth, we have excellent welding safety features, procedures, and personal protective equipment available to reduce risks so we can safely enjoy our hobby.

A must-have for the hobbyist welder, an affordable auto-darkening welding helmet provides excellent eye protection and peace of mind.

The technology in our helmets lets us safely choose a comfortable darkness level without worrying about what shade lens to use for MIG welding.