Choosing a Gas Tank Size for MIG or TIG Welding

If you’re new to MIG or TIG welding, you probably don’t know how much welding you’ll do, let alone how much welding gas you’ll go through.

But it makes sense to have some idea of how long a welding gas bottle will last before deciding what size cylinder to buy.

I’ll show you how much welding time to expect from the most popular cylinder sizes used by hobbyists. Then you can compare physical dimensions to make sure the bottle will fit in your vehicle or welding cart.

You’re just a quick read away from knowing what size welding gas cylinder to choose.

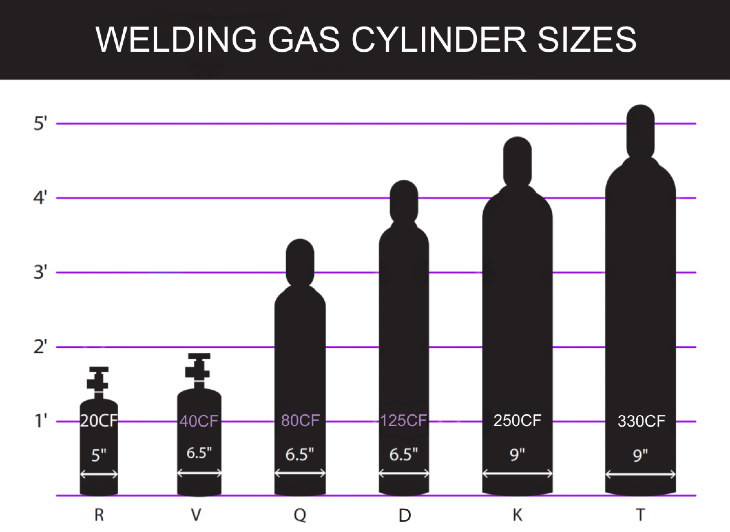

Popular Welding Gas Bottle Sizes for MIG and TIG

While you can get a welding gas tank in many other sizes, most welders choose a cylinder with a size of 40, 80, or 125 cubic feet (cf) with MIG mixtures or Argon gas for TIG.

With 125 cf, the larger tank provides plenty of welding time between refills. It’s a bit more awkward to handle because of the added weight and length, but it’s easy enough to move around and lift for most people.

You can carry the smaller 40 cf bottle to the job site with one hand, so it’s perfect for remote work, or low-volume users.

Most casual welders find the 80 cf cylinder size hits the mark with a balance of run time and ease of handling.

Recommended Argon/CO2 MIG Bottle Sizes

Because they’re all around 7 inches in diameter, choosing any popular tank size takes up the same space on your shop floor and will fit in the same tank holder or cart.

However, consider that the taller and heavier 125 gas tank may exceed the capacity of a light-duty welding cart. An overloaded cart can become unstable and difficult to move around your shop safely.

Because you never want to run out of gas or refill a tank before it’s completely empty, you’ll probably end up with two tanks of your primary gas. You can always go with tanks of the same size, or go with one large 125 cf tank, and a small 40 cf for backup. That gives you a portable tank for minor jobs away from the shop.

It’s important to know that you really don’t need to worry about choosing the wrong size because most gas retailers are good about swapping sizes for the straight difference in price.

Recommended 100% Argon TIG Bottle Sizes

Welding Gas Cylinder Specifications (Argon/MIG Blends)

Keep in mind that specifications vary among compressed gas cylinder manufacturers. And because you may see a high-pressure cylinder labeled by a letter, number, or content weight, I’ve also included this information in the chart.

| Size | 40 cf (#2/V) | 80 cf (#3/Q) | 125 cf (#4/D) |

|---|---|---|---|

| Height | 22 in. | 35 in. | 45 in. |

| Diameter | 6½ – 7¼ in. | 6½ – 7¼ in. | 6½ – 7¼ in. |

| Empty Weight | 24 lbs. | 47 lbs. | 58 lbs. |

| Full Weight | 28 lbs. | 56 lbs. | 71 lbs. |

| Full Pressure | 2015 PSI | 2015 PSI | 2265 PSI |

Small tanks of 20 cf or less capacity aren’t commonly used to TIG or MIG weld. You see these tanks used in portable oxy-acetylene gas welding kits.

While larger cylinders over 125 cf are available, very few are customer-owned, instead, most are leased or rented from the gas supplier.

Because these enormous tanks are tough to handle and may cause damage or injury if dropped, they’re usually delivered by the supplier to high-volume customers.

Of course, the larger the tank, the more economical the refills. While you won’t pay much more to get twice the gas, the savings won’t offset the ongoing tank rental cost for low-volume users.

My last purchase of an 80 cf cylinder from a “local” supplier 20 miles from my home took about an hour and a half of my time and cost way more than it should have.

I ended up “purchasing” a tank that was not new, needed a new hydro-test in just five years, and had the gas company’s name stamped on the neck ring.

To top it off, the fine print on my receipt stated the tank was refillable only by them!

At that time, I didn’t realize there was an easier way. I thought all the cylinders for sale online were empty.

A Better Way to Buy a Full Welding Tank

Later, I learned that I could have a full 80cf cylinder delivered to my door at a great price. These bottles meet DOT standards and are hydro-tested.

The company guarantees the tank will have a minimum of eight years left on the hydro-test. Just don’t confuse the “2015” pressure stamp for the test date when checking.

Because they come with a blank neck ring, the tanks are refillable by a supplier of your choice.

Any decent gas supplier won’t have a problem refilling a good quality customer-owned cylinder. Some large outfits don’t want to deal with low-volume users, so it’s a good idea to check your local options.

I recommend looking for a small, helpful gas supplier like the one in this video. He shows what cylinder sizes are popular with hobbyists, along with what to look for when buying gas cylinders.

100% CO2 Gas Cylinders for MIG

For greater penetration and lower-operating costs, some prefer to use pure carbon dioxide instead of a MIG mixture.

The 100% CO2 gas cylinders used for MIG welding differ from MIG blends or an Argon tank.

What to know:

- CO2 tanks use different valves so you’ll need an adapter.

- CO2 tanks are filled by weight, instead of volume.

- One pound of CO2 provides 8.741 cf of shielding gas.

- Freezing can damage a regulator not rated for 100% CO2.

100% CO2 (C100) Cylinder Sizes and Operating Time

| Size | H x W (in) | CU FT | Time* |

|---|---|---|---|

| 1.25# | 10.5 x 3 | 10.9 | 33 min. |

| 5# | 18.25 x 5.5 | 43.7 | 2.2 hrs. |

| 10# | 20.5 x 7 | 87.4 | 4.4 hrs. |

| 20# | 27.5 x 8 | 174.8 | 8.8 hrs. |

| 50# | 47 x 8 | 437.1 | 21.9 hrs. |

Related: MIG Welding with 100% Argon Shielding Gas

How Long Does Welding Gas Last?

How much welding time you’ll get per bottle will depend on the flow rate you set on the regulator. The setting is usually between 10 and 40 cubic feet per hour (cfh) depending on the work environment.

You’ll need a higher flow rate to maintain shielding gas protection in a windy area. Even with my garage door open 12 inches, I get good results with the regulator set to 20 cfh for MIG as long as it’s calm.

Since we’re dealing only in cubic feet, our welding-time calculation for gas cylinders is simple:

Gas welding time (hours) = [cylinder volume (cf)] / [flow rate (cfh)]

So, using my 80cf cylinder, with the regulator set to 20 cfh, then:

Welding Time = (80 cf) / (20 cfh) = 4.0 hours

Welding Time Calculated for Cylinder by Gas Flow Rate (Argon/MIG blends)

| Flow rate | Tank Size | ||

|---|---|---|---|

| 40 cf | 80 cf | 125 cf | |

| 10 cfh | 4.0 hrs | 8.0 hrs | 12.5 hrs |

| 15 cfh | 2.7 hrs | 5.3 hrs | 8.3 hrs |

| 20 cfh | 2.0 hrs | 4.0 hrs | 6.3 hrs |

| 30 cfh | 1.3 hrs | 2.7 hrs | 4.2 hrs |

| 40 cfh | 1.0 hrs | 2.0 hrs | 3.1 hrs |

Of course, these are calculated times and your real-life results will vary. Significant temperature swings, the frequency of start and stops, and pre/post-flow settings will affect your actual run time.

More about pre/post flow: Features of Advanced MIG Welders under $1500

It’s a good practice to check your regulator occasionally as you weld. As the gas level decreases, the cylinder pressure drops, causing the flow rate to change on single-stage regulators. Again, temperature changes have the same effect, so don’t be surprised if you’re adjusting the regulator more often than you expected.

I’ve picked up the habit of backing out the gas regulator adjustment to “0” when I finish welding for the day. Manufacturers recommend this to remove spring pressure from the valve diaphragm. This practice also forces me to adjust gas flow the next time I weld.

Read all about: MIG Welding with 100% CO2 Shielding Gas

How Much Gas is Left in the Tank?

With 100% CO2, you’ll need to weigh the tank to know how much remains.

With Argon and Argon/CO2 blends, the pressure gauge provides an estimate of the remaining gas.

With a full welding gas cylinder at 70 degrees, the pressure gauge should read near the working pressure stamped near the neck. This is usually 2015 or 2265 psi.

Without a drastic temperature change or a leak, you can expect the pressure to respond in a straight line to the remaining gas volume.

So, if your full cylinder started with 2000 psi on the pressure gauge, a reading of 1000 psi tells you that roughly 50% of your gas remains.

Some pressure gauges are more accurate than others, especially in the lower range. But as long as the regulator is maintaining the set flow while the trigger is pulled, you can keep on welding, knowing that your weld is protected.

Don’t be concerned if you notice the gauge seems to hold steady for a time, then suddenly drops. The slow gas discharge rate that we use in welding can cause the pressure dial to hang up temporarily. It won’t take long before you get a feel for the accuracy of your pressure gauge.

Conclusion

Now that you’ve seen how long welding gas will last and the most popular tank sizes, I hope you know what size welding gas cylinder is right for you so you can get started with MIG or TIG welding soon!