Why You Need Grinding Mode on Your Next Welding Helmet

It’s all about safety and productivity.

A welding helmet with grind mode includes an option to improve visibility during the grinding process by setting the lens shade at the lowest level.

It eliminates the need to switch to a grinding shield.

How Does Grind Mode Work?

To understand how the grind mode on a welding helmet works, it’s helpful to know the two primary functions of an auto-darkening filter (ADF).

First, it’s a filter designed to block invisible light-UV and IR radiation emitted from the welding arc. These are harmful rays that cause serious short- and long-term damage to your eyes.

The filter is a coating on the lens that creates the default shade level, which is usually around a #3. This is bright enough to set up or inspect the weld.

Because it’s a lens coating that doesn’t rely on power, the filter protects your eyes from dangerous radiation at all times. With an ADF built to ANSI Z87.1 standards, the filter alone will protect you up to the darkest shade setting of the helmet.

Second, the ADF auto-darkens the lens. It’s designed to reduce visible light so you can comfortably view the arc and weld pool. Sensors detect the arc and darken the shade quickly, so your eyes aren’t affected and attempt to adjust.

Sparks from grinding operations are not bright compared to a welding arc but are picked up by arc sensors. If the helmet detects sparks while in weld mode, it will darken to a solid black screen.

By switching to grind mode, you disable the auto-darkening function so it isn’t triggered by sparks. The lens remains in its default state, so you have visibility to work while your helmet protects your face and eyes from the metal debris.

A look through the lens at grind mode

Different Ways to Use Grind Mode

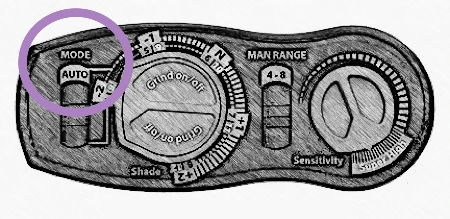

Internal Grind Control

A small button, knob, or switch on the inside of the helmet activates the mode to grind on some models. This is the most inconvenient placement of the control.

You’ll need to tilt the hood up a bit, remove a glove, reach your hand up in front of your face and find the small switch while being careful not to disturb other important settings. Usually, you’ll just end up removing the helmet to make the change.

You’ll go through this operation each time you want to switch from weld mode to grind mode, and back again. This quickly gets old if you often need to jump back and forth.

Many older helmets have no indicator to alert you when in grind mode, so it’s possible to forget it’s on.

If you weld in grinding mode, you will experience a bright flash. It’s not fun, and you’ll need to take a break until your vision recovers, but you’re not exposed to damaging radiation.

Operators frustrated with inside switches often skip using grind mode. They’ll lift the mask and rely on safety glasses for protection.

It’s easy for bits of metal to ricochet past glasses or even a mask on its own. Good welding safety calls for doubling-up and wearing both.

A grind control switch mounted inside the helmet is not user-friendly or efficient. Grind mode is a useful feature, but there are better options available.

External Grind Control

When mounted to the outside of the welding helmet, a control switch becomes much more convenient for the welder. You can enable grind mode without lifting or removing your hood, but you may still need to remove a glove to operate the control.

Other than the position of the control, the function remains the same. It’s still a manual operation, where you’re responsible for the setting.

Because we usually find this feature on a newer auto-darkening lens, you can expect a reminder that grind mode is active. You may also benefit from improved overall useability and better optics.

This affordable Antra is a lightweight helmet with external grinding mode control and good optics.

One downside to external switches is the risk of damage from spatter or impact. I think the benefits far outweigh this risk. Because you’re more likely to use this feature with an external switch, you’ll be safe and more productive.

Auto Grind Control

Fully automatic darkening, as found on this Optrel welding helmet, reduces the chance of human error. Grinding sparks don’t fool its advanced sensors, so they won’t over-darken your view.

It detects changes in brightness between any welding activity and adjusts the shade as needed. You can go about your work and let the latest tech handle shade adjustment.

This technology is costly, but it makes welding more convenient and productive, whether you’re a professional or a hobbyist.

Flip-Up Shield

A few models, like this Miller welding helmet offer a handy option some welders prefer.

The auto-darkening lens can rotate up and out of view, leaving a clear protective shield. Made of polycarbonate, it meets requirements for high-impact eye and face protection. But because it has no filter, it doesn’t reduce brightness or harmful rays.

It’s ideal for weld preparation, inspection, and even grinding. Compared to a #3 shade, which reduces brightness by 87%, a clear shield makes details more visible and reduces eyestrain.

If you have trouble seeing details, another option is to improve your work area lighting or even try a welding helmet light.

With this type of helmet, you must remember to lower the ADF before welding or risk real eye damage. While the models I’ve checked out also have a traditional mode for grinding, it’s usually located inside the helmet.

The Bottom Line

Grind mode on a welding helmet is a must-have feature. But if it’s not convenient to use, it’s not useful.

Fortunately, helmets with external switches you operate manually are becoming more affordable. Or you could invest in state-of-the-art technology for a helmet that takes care of you by turning on grind mode automatically.