110-volt MIG welders are portable, handy tools you can power from a standard outlet. And while designed for light-duty home use, the best 110V MIG welders are also versatile.

For example, with car restoration, a 110V MIG welder repairs heavy suspension components with multiple passes at full power. Then, at a low setting, it makes precision spot-welds on thin body panels.

Even the best MIG welders on the market vary in cost, quality, and function. The best choice for others may not be useful to you. That’s why you’ll see seven recommendations for different needs.

Other than my favorite, the Hobart 140 MIG Welder, the picks are in no particular order.

Jump to: Top 110V Pick | Most Portable | Best 110V Value | Budget MIG | Budget Multi-Process | Lincoln’s Best 110V MIG | Premium Choice

Compare Top 110V MIG Welders

Review the 7 Best 110V MIG Welders

Hobart Handler 140 – Top 110V MIG Welder

- A long-time favorite MIG welder of hobbyists and homeowners using 120-volt household power

- Dependable, straightforward operation is ideal for learning to weld

- Rugged build designed for years of trouble-free welding

As much as I enjoy technology—including gear with every bell and whistle—I appreciate this “meat and potatoes” welder.

For home use, I recommend the dependable and easy-to-use Hobart Handler 140 as the best 110V MIG welder.

Assembled in the USA, the Hobart 140 (#500559) is a tried and tested favorite of home hobbyists, classic car restorers, and metal artists. It’s well built. With a proven transformer-type power source and wire feed drive system, this Hobart provides a trouble-free MIG welding experience.

You might even pass this welder on to the next generation.

The 140-amp top-end is as powerful as you’ll find in a 110-volt MIG welder.

It’s enough to weld 3/16-inch mild steel in one pass or 1/4-inch with multiple passes, making it good for most automotive work. Dial down the 5-position voltage control to the minimum setting of 25 amps and weld auto body panels as thin as 24 gauge.

They mark the wire feed speed control 10 through 100 for reference, although it is infinitely adjustable between 40 and 700 inches per minute (IPM) to fine-tune the welding arc.

The lack of spool gun compatibility is a shortcoming of this welder.

However, it’s rated to weld 12 to 16-gauge aluminum. Few manufacturers risk this recommendation. That’s because their wire drive system must be capable of pushing soft aluminum wire at high speed through the entire gun cable without birdnesting, crushing, or jamming the wire.

Hobart’s 140 is up to the task. With this welder (and a little patience), I MIG welded 1/8-inch aluminum without a spool gun.

Any wire drive that easily handles aluminum wire will have no trouble with easier to feed solid and flux-core wires.

At the heart of any good wire feed welder is a reliable wire feed system. It’s a must-have for trouble-free MIG welding and the first thing I look for when researching a welder.

With a quick change drive roll and calibrated tension control, the Hobart 140 has one of the best single-roller drive wire feed systems.

Specifications

| Process Type | MIG and flux core |

| Input Voltage | 110V/115V/120V |

| Output Amperage | 25 – 140A |

| Duty Cycle | 20% @90A/18.5V |

| Weld Thickness | 24 ga. – 1/4 in. |

| MIG Cable | 10 ft. |

| Ground Cable | 10 ft. |

| Weight | 57 lbs. |

| Dimensions (in.) | 12.375(h) x 10.625(w) x 19.5(d) |

| Warranty | 5/3/1 year(s) depending on component |

| Owner’s Manual |

Upshot

While not the cheapest, lightest, or most versatile MIG welder, the Hobart 140 is affordable, handy, and does exactly what it’s designed for.

It reliably welds mild steel, stainless steel, and light aluminum.

Backed by a strong warranty covering the transformer for 5 years, including labor, it’s my choice for the best 110V MIG welder. It’s ideal for most hobbyists and home use.

Related: see the full Hobart Handler 140 Review.

Pros

- Reliable wire feed drive

- Simple to use

- Long-lasting build quality

- Affordable

- Good warranty

Cons

- No spool gun option

- Work clamp is small; no bonding cable

Forney 140 Easy Weld FC-i – Most Portable 110V Flux Core Welder

- Great for remote work locations because it's easy to carry and you can weld anywhere with access to standard wall socket

- No bulky and expensive gas cylinders needed

- Ideal for DIY welding projects and general maintenance or repair work around the home, farm or ranch.

At just 19 pounds, the Forney 140 FC-i MIG Welder (#261) is the easiest to carry 110V MIG welder.

You can make room for this small and lightweight tool in any vehicle. Take it to your next project, or keep it with you so you’re prepared for the next repair.

Now, there is a trade-off for this portability.

Because this is a flux core only, or gasless, welder, you’ll deal with slag, and more smoke and spatter than a true MIG welder. And you won’t be able to hook up shielding gas and use solid welding wire for cleaner welds or take on any aluminum work.

Thanks to a lightweight and efficient inverter power source, you won’t give up power for this small package.

Using a 4-inch wire spool keeps this machine light to carry. For large jobs, there’s room for an 8-inch spool.

On a 20A circuit, the 140 FC-i develops 140 amps so you can weld up to 1/4-inch mild steel. Infinitely adjustable voltage and wire speed provide precise control for thin sheet metal down to 22 gauge.

Forney machines have a 30-day warranty against defects in materials or workmanship and a 1-year warranty on all internal electrical components that cannot be accessed without removing the cover.

You are responsible for transportation to and from the manufacturer, or an approved repair facility. There are 150 facilities in the US. Be sure to register your purchase with Forney or you won’t be eligible for warranty service.

A few owners complained about slow wire feed speed (WFS) with the 140 FC-i welding machines. Not able to find the WFS specs in the product literature, I contacted Forney. They told me that the 140 FC-i operates from 47 to 173 inches per minute (IPM). This is without a load and at any voltage setting.

Specifications

| Process Type | Flux Core Welder |

| Input Voltage | 110V/115V/120V |

| Output Amperage | 32 – 140A |

| Duty Cycle | 30% @ 90A |

| Weld Thickness | 22 ga. – 1/4 in. |

| MIG Cable | 8 ft. |

| Ground Cable | 8 ft. |

| Weight | 19 lbs. |

| Dimensions (in.) | 12 (h) x 8.125 (w) x 16.75 (d) |

| Warranty | 1 year |

| Owner’s Manual | PDF download (not viewable in the browser) |

Upshot

For some of us, an ultra-portable, 110V, flux core welder such as the 140 FC-i MIG could be the only welder ever needed. It makes easy work of quick repairs and occasional small projects around the home.

For me, using the 140 FC-i as a simple go-anywhere welding tool is appealing.

Too many times, I’ve lugged 70 pounds of MIG welder to a location only to make a 30-second flux core weld. Having one of these available for home use, or in your work truck, RV, or toy-hauler could save the day (you know it will!).

Pros

- Easy to carry and store

- No gas cylinder required

- Weld anywhere with 110V

- 4000-watt generator approved

Cons

- Messy flux core welds

- Short warranty

- Warranty work can be difficult and costly

Hobart Handler 210 MVP – Best Overall Value 110V MIG Welder

- Switching voltage is quick and easy with Hobart's MVP system. All you need to do is change the plug - no tools required, and it's easier to store than a cable.

- A rock-solid 115V MIG welder that gets even better on 230V power

- Get all-around versatility for auto body sheet metal repairs to heavy-duty fabrication—it even welds aluminum

Although costlier than most want to spend on a first welder, this is one of the best MIG welders. It’s a (very) close runner-up to the top pick.

Concerned about quickly outgrowing a 140-amp MIG welder?

The Hobart 210 MVP (#500553) is an affordable way to prevent that from happening.

Hobart fit 210-amps of heavy-duty welding power plus dual-voltage versatility, in a package the same size as Hobart’s 140-amp machine.

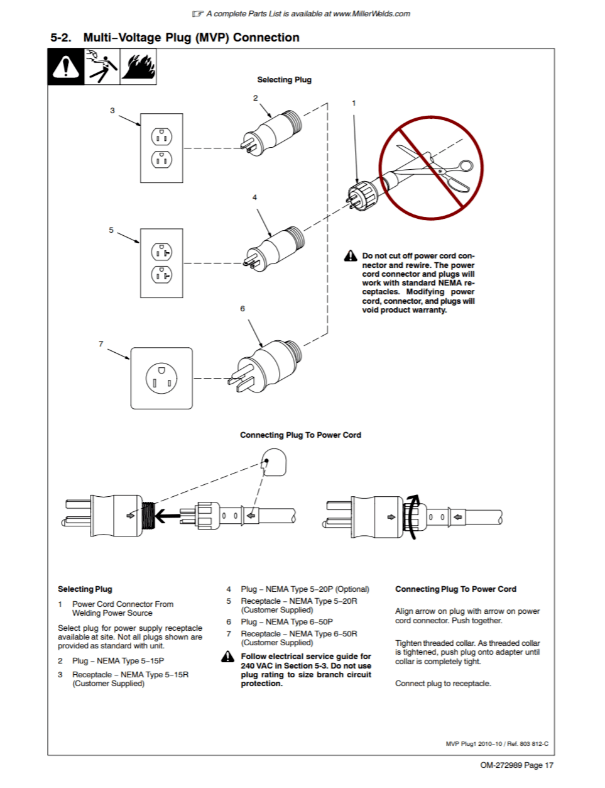

Swapping over from 115V to 230V is quick and easy. With Hobart’s MVP (Multi-Voltage Plug) system, you change only the plug. Without tools. And, unlike other multi-voltage systems, you don’t have the hassle of storing an extra power cord.

MVP Plug Types:

- 115V/15A − NEMA Type 5-15P (included)

- 230V/50A − NEMA Type 6-50P (included)

- 115V/20A − NEMA Type 5-20P (available)

You have 140-amps of MIG welding power while running on a 110V (20-amp) household outlet. Switch to 230V power and get up to 210 amps. That’s enough juice to weld 3/8-inch mild steel.

Seven voltage settings and infinitely adjustable WFS provide control of the arc. Join sheet metal as thin as 24 gauge.

To efficiently weld up to 1/4-inch aluminum, connect the optional SpoolRunner 100 spool gun. The short feed distance of this gun eliminates feed issues common with soft aluminum wire, such as bird-nesting.

Specifications

| Process Type | MIG, Flux Core |

| Input Voltage | 115V/230V |

| Output Amperage | (115V): 25 – 140A (230V): 25 – 210A |

| Duty Cycle | (115V): 20% @ 90A (19V) (230V): 30% @ 150A (23V) |

| Weld Thickness | 24 ga. – 3/8 in. |

| MIG Cable | 10 ft. |

| Ground Cable | 10 ft. |

| Weight | 79 lbs. |

| Dimensions (in.) | 12-3/8(h) x 10-5/8(w) x 19-1/2(d) |

| Warranty | Warranty: 5/3/1 yr(s) depending on component |

| Owner’s Manual |

Upshot

A perfect choice if you’re considering the Hobart 140, but might outgrow a straight 110-volt MIG welder. Like the 140, the 210 MVP is user-friendly and reliable, but with more power and versatility.

It gives you more options when choosing projects.

The Hobart 210 MVP represents an affordable balance of durability, capability, and ease of use. It’s the best value in 110V MIG welders.

Pros

- Heavy-duty build quality

- Runs on 115V or 230V power

- Spool gun ready makes for easy welding of aluminum

- Compact size

- Reliable wire drive system

Cons

- Heavy for a portable welder

- Fixed voltage control levels

Lotos MIG140 – Top Budget 110V MIG Welder

- A low-cost alternative to the Hobart 140 for MIG welding powered by a standard wall outlet

- This one welds aluminum with an optional spool gun, which is not available for the small Hobart welder

- They include the gas regulator, so all you need is a gas cylinder for clean MIG welding

Revamped a few years back, the Lotos MIG140 now includes several unexpected features at its price.

Lotos made this 110v MIG welder spool gun ready and now offers an affordable spool gun option. Together, this makes a dependable kit to weld 1/8-inch aluminum for less than the price of a brand name MIG welder alone.

Digital readout displays for infinitely adjustable voltage and wire feed speed controls allow you to recreate your favorite settings with precision.

A more reliable drive system made of cast aluminum features a calibrated tension control and tool-less roller changes.

Here’s a business owner that really puts a Lotos MIG140 to work. He’s impressed with the wire feeder.

An unusual feature in a budget MIG welder, the 2T/4T switch lets an operator release the trigger while welding long runs. Most of us won’t ever use this. But it’s useful if you need it.

Polarity changes are quick and easy thanks to tool-less front panel connectors.

While generic, the MIG torch is nice. At 10 feet, it’s long enough and includes a quick-connect fitting to the welder. Lincoln-style contact tips fit this welding gun.

Please don’t let the cheap accessories included with this welder affect your decision to buy. Lotos could do themselves a big favor by not even including these “throw-in” items. They add no value and I wouldn’t recommend you use them.

Specifications

| Process Type | MIG, Flux Core |

| Input Voltage | 110V/115V/120V |

| Output Amperage | 25 – 140A |

| Duty Cycle | 20% @ 90A/18V |

| Weld Thickness | 24 ga. – 3/16 in. |

| MIG Cable | 10 ft. |

| Work Cable | 8 ft. |

| Weight | 54 lbs. |

| Dimensions (in.) | 12(h) x 8.125(w) x 16.75(d) |

| Warranty | 30-day satisfaction, 1 year limited |

| Owner’s Manual |

Upshot

Cheap accessories aside, these guys have put together an attractive 110V MIG machine for hobbyists. Especially if you’re trying to keep costs down but need to weld a fair amount of light-gauge aluminum.

If you need to weld heavier aluminum up to 1/4 inch, the Hobart 210 MVP is a better choice.

But if long-term satisfaction is more important than spool gun capability, I’m going with the Hobart 140.

Pros

- Nice MIG torch

- Spool gun ready

- Digital read-out displays

- Easy polarity changes

Cons

- Poor-quality accessories

- Customer pays warranty shipping both ways.

Forney Easy Weld 140 MP – Top Budget Multi-process 110V MIG Welder

- Expand your welding possibilities with this upgraded Forney machine capable of true MIG, flux core, TIG and stick welding

- Perfect for various light-duty homeowner projects on standard household power

Maybe you prefer a go-anywhere type of welding machine, such as the previously covered Forney FC-I, but need more versatility than a flux core welder offers.

In a nearly identical package, the Easy Weld 140 MP is a 110V multi-process welder that comes ready to flux core and stick weld. Plus, it’s capable of true 110V MIG welding using solid wire and shielding gas.

But you must spring for the gas regulator and hose that’s not included with this welder.

The 140 MP is not spool gun capable.

But you can try your hand at TIG welding. Just add a TIG torch and 100% Argon gas. This machine uses a lift arc start technique. And remember, this is DC TIG, so it cannot weld aluminum.

Specifications

| Process Type | MIG, Flux Core, Stick, TIG |

| Input Voltage | 110V/115V/120V |

| Output Amperage | 10 – 140A |

| Duty Cycle | 30% @ 90A |

| Weld Thickness | 22 ga. – 1/4 in. |

| MIG Cable | 10 ft. |

| Work Cable | 8 ft. |

| Weight | 20 lbs. |

| Dimensions (in.) | 12(h) x 8.125(w) x 16.75(d) |

| Warranty | 30-day/1-yr. internals |

| Owner’s Manual |

Upshot

Yes, Forney made compromises to maintain portability in such a flexible 110V welder. If you’re not interested in aluminum work, the Easy Weld 140 MP offers a ton of options bundled in a package that’s easy to transport.

It’s the best option for a budget-priced multi-process 110V MIG welder.

Pros

- Multi-process: Flux core and stick ready out of the box

- MIG and TIG capable with purchase of accessories

- Easy to carry and store

- Weld anywhere with 110V

- 4500-watt generator rated

Cons

- Gas regulator and hose sold separately

- No aluminum welding capability

PowerMIG 210 MP – Lincoln’s Best 110V MIG Welder

- It's lightweight for easy transport and it will run on either 110 or 230 volts, so all you need is a outlet

- Easy to use color LCD screen walks you through setup procedures and clearly displays your options

- You can weld with MIG, TIG, and stick processes so you have options to handle more projects and different types of metals

While the Lincoln Electric 210 MP is one of the best MIG welders here, its higher price took it out of the running for the overall top choice. But loyal fans don’t mind paying a little more money for Lincoln’s top-notch equipment.

Plus, this welder hits the mark for hobbyist welders in several ways.

Featuring a color LCD screen to walk you through setup procedures, the 210 MP is extremely user-friendly.

This machine helps you get set up to weld. You won’t need to dig out the owner’s manual every time you want to make a quick repair.

The intuitive interface is enjoyable to use, even for advanced users.

This multi-process welder comes ready to weld with MIG, flux core, and stick processes.

Connect a Lincoln K3690-1 TIG kit (not included) to add TIG welding to your tool bag. Because this is a DC-current TIG process, it is not suitable for aluminum work.

Fortunately, the compatible K3269-1 Magnum PRO 100SG spool gun turns the 210 MP into a strong aluminum welder.

At the heart of this welder sits a beefy, wire drive system made of cast aluminum. Almost eliminating any chance of a birdnest, Lincoln Electric used interchangeable wire guides around the rollers.

The 210 MP has the flexibility to operate from 120V or 230V power. But unlike the Hobart/Miller system, Lincoln requires swapping the entire power cord to change voltage. This means you’ll have an extra cord to store and keep track of.

If you plan to take your welder to worksites, you’ll appreciate how easy to carry this machine is. Because of its lightweight inverter power source, the Lincoln 210MP weighs just 40 pounds.

Specifications

| Process Type | MIG, Flux Core, Stick, DC TIG |

| Input Voltage | 110/115/120V & 230V |

| Output Amperage | (120V): 20 – 140 (230V): 25 – 210A |

| Duty Cycle | (120V): 40% @100A/19V (230V): 25% @200A/24V |

| Weld Thickness | MIG: 24 ga. – 5/16 in. Flux Core: 20 ga. – 5/16 in. Aluminum: 18 ga. – 3/16 in. |

| MIG Cable | 10 ft. |

| Work Cable | 10 ft. |

| Weight | 40 lbs. |

| Dimensions (in.) | 14(h) x 10.8(w) x 19(d) |

| Warranty | 3 years |

| Owner’s Manual |

Upshot

If you’re considering a 110-volt MIG welder that will also run on 230-volt power but need a machine that’s easy to haul to the job, the 210 MP is a strong choice.

It’s more money, but half the weight of the Hobart 210 MVP. Plus, you’ll gain stick and TIG options and a handful of advanced features not found on the Hobart.

The PowerMIG 210MP is Lincoln Electric’s best 110V MIG welder.

Pros

- Easy to carry – only 40 lbs.

- Simple setup with LCD screen

- Dual cooling fans

- Multi-process

- Dual voltage

Cons

- Expensive

- Cooling fans are always on

Miller Multimatic 215 – Top Premium 110V MIG Welder

- A multi-voltage and multi-process welder ready for MIG and stick welding that can also weld DC-TIG with the addition of a kit. It's perfect for those who want to take on any project.

- The Miller Auto-Set menu is more efficient and user-friendly, and the display is so much easier to see

- Cooling fans run only when needed for quieter operation and fewer contaminants pulled through the machine

Now, if you think the Lincoln 210 MP is not sophisticated enough, look at the Miller Multimatic 215. With features and abilities similar to the Lincoln, the 215 is more refined.

It also may be the easiest to use 120V (or 240V) MIG welder.

This is a multi-voltage machine capable of using 120V or 240V input.

Like the Hobart 210 MVP, you only swap the plug-end when changing voltage sources. It’s a tool-less process. The unused plug is stored inside the welder, so it’s not left behind or lost.

This is a multi-process welder ready for MIG, flux core, and stick welding processes. It welds DC-TIG with the addition of the Miller TIG kit.

This welder even includes an extra gas port so you can keep your MIG gas and 100% Argon gas cylinders connected at the same time. You’re free to jump back and forth between processes, as needed—without stopping to switch tanks.

While Lincoln’s weld setup procedure is helpful, I think the Miller Auto-Set menu is even more efficient and user-friendly. It’s helpful to see the current process displayed on the front panel without having to access the screen.

I also think the Miller LCD screen is easier to view. See for yourself in this quick demo video.

The Miller Spoolmate 100 and 150 spool guns are plug-and-play compatible with the Multimatic 215. The welder automatically detects the spool gun, so no forgetting to flip a switch.

You can even use Auto-Set with a spool gun. Just run the built-in program to calibrate the gun to the welder for easy and reliable aluminum welding.

A simple feature is one of my favorites: Fan-on-demand.

It just makes sense that cooling fans should only run when needed. The 215 provides relief from that constant drone, and it pulls less smoke and dust through the welder.

This welder has a top-center mounted handle similar to most portable welders. But Miller added convenient handles at each end to make moving the machine more comfortable and secure. They give you more control when hoisting this machine in and out of a vehicle.

Specifications

| Process Type | MIG, Flux Core, Stick, DC TIG |

| Input Voltage | 110V/115V/120V & 240V |

| Output Amperage | (120V): 30 – 125A (240V): 30 – 230A |

| Duty Cycle | (120V): 60% @110A/19.5V (240V): 20% @200A/24V |

| Weld Thickness | MIG: 24 ga. – 3/8 in. steel Flux Core: 18 ga. – 3/16 in. TIG: 24 ga. – 1/4 in. steel Stick: 16 ga. – 3/8 in. steel |

| MIG Cable | 10 ft. |

| Work Cable | 10 ft. |

| Weight | 40 lbs. |

| Dimensions (in.) | 12.5(h) x 11.25(w) x 20.5(d) |

| Warranty | 3 years on welder, 90 days on gun |

| Owner’s Manual |

Upshot

As a premium welder, the Miller Multimatic 215 packs a lot of “nice to have” features in a compact package.

Not everyone will use or appreciate all that this welder offers, and that’s okay. You can buy an outstanding 110V MIG welder that gets the job done for a fraction of the price of the 215.

But, if you enjoy technology and how useful and considerate features create a tool you look forward to using, the Miller 215 could be for you.

Pros

- Easy to carry – under 40 lbs.

- Simple setup with LCD screen

- Fan-on-demand

- Dual gas ports

- Dual voltage

Cons

- Expensive

- Higher minimum amperage can limit control on thin metals

Considerations when buying a 110-volt MIG welder

110, 115, or 120-volt, does it matter?

Not at all, the ANSI C84.1 electrical power standard allows an acceptable operating range for a nominal 120-volt circuit of 108-126V. Manufacturers make independent decisions to rate their welders at different points on this scale.

However, it is important to know that they rate most 110V welders for use on 20-amp circuits. The problem is that most household outlets are only 15-amps. Welders will run on 15-amp circuits with reduced performance and duty cycles (or tripped breakers).

What are duty cycles?

Manufacturers provide duty cycle ratings to show how long a welder can operate at a certain power output level.

A typical 110V MIG welder duty cycle rating looks like this: 20% @90A (19V). This tells you that when producing 90 amps of output, this welder should operate for a maximum of 2 minutes (20%), and rest (cool down) for 8 minutes, during a ten-minute period.

Exceeding the duty cycle could overheat the machine causing the thermal overload relay to trip. Thermal overload protection prevents further welding until the cooling fan(s) dissipate the excess heat.

If this is a 140-amp welder, the example duty cycle shows the welder operating at about 2/3 power. Duty cycles vary inversely with the output power. Increasing the output will reduce the duty cycle while decreasing output will increase the duty cycle.

Cooler-operating and more efficient than transformer machines, inverter-based welders have higher duty cycles that don’t vary as much with output settings. An example is the Multimatic 215 with a 60% duty cycle @ 110A on 120V power.

In reality, few hobbyists have duty cycle issues while adequate power is supplied to the welder. This means running on a dedicated 20-amp circuit, and using a properly sized extension cord only when necessary.

Video tips to get the most from your 110V welder on thick materials:

Which is the best power source, inverter or transformer?

Many welders use transformers to convert 110V household current into high-amperage welding power. Developed over the past century, modern transformers are very reliable, but remain heavy and generate a lot of heat.

In the 1990s, manufacturers started to develop a lighter, more efficient, and cooler-running welder using modern electronics and programming. The resulting inverter-based power sources also provided improved arc control with a variety of materials and conditions.

Early units were costly and not as reliable. Today’s inverter welders have improved in both areas but still cannot match the longevity of a quality transformer machine.

Many consider a shorter life span a reasonable trade-off for improved portability and up to 20% energy savings from modern inverter welders.

Flux core (gasless) vs. MIG (gas-shielding) welding

Every welder I’ve included in this article can weld with flux-core wire. This is a hollow wire filled with shielding flux. During welding, heat vaporizes the flux which protects the weld from contaminants.

We know this process as flux-cored arc welding (FCAW), or gasless welding.

Flux Core Pros

- Ultra-portable with no gas cylinder, hose or regulator.

- Works well in outdoor conditions, even in a light breeze.

- Can handle slightly dirty materials (light rust, grease, etc.).

- Deeper weld penetration.

- Fast rate of material deposited to the weld.

- Easier welding in awkward positions.

Flux Core Cons

- Creates slag (flux and contaminant residue) that you must remove with a chipping hammer and brush.

- Creates more smoke, sparks and spatter (molten weld material deposited outside the weld bead).

- Spatter may need grinding to remove.

- Not as effective on thinner metals.

- Not suitable for aluminum welding.

Except for the Forney 140-FCi, every welder covered here is also capable of true MIG welding. “MIG” is short for metal inert gas and also known as gas metal arc welding (GMAW), this process uses solid metal welding wire with separate shielding gas to protect the weld.

To get started, you’ll need a cylinder of MIG shielding gas. Connect the cylinder to your welder using a gas regulator/flow gauge and hose. Learn about choosing a gas cylinder for MIG welding.

MIG Pros

- A smooth arc with less smoke, sparks, spatter, and no slag.

- Quick wire brush clean-up.

- Better control (less burn-through) on thin metals.

MIG Cons

- Even a slight breeze can disturb the shielding gas causing poor-quality welds.

- Must purchase, transport, store, and occasionally refill a shielding gas cylinder.

What about always “hot” guns?

Some inexpensive welders do not use a trigger relay to electrify the welding gun. Instead, anytime the power is on the gun becomes energized (hot).

Welders using this design are unsafe, and I do not recommend their use.

Do multi-process welders make good all-around machines?

The multi-process welders I picked are some of the best MIG welders that also perform other welding processes. They may, or may not, handle secondary duties at the same level as a dedicated, single-process welder.

However, good quality multi-process welders, such as the Lincoln 210 MP, offer exceptional flexibility and convenience.

On the fence?

You can learn a lot about a welder (and its manufacturer) by reading the instruction manual or contacting them with a question or two.

A simple-to-read and complete manual shows that the manufacturer cares about customer satisfaction and probably knows what they’re doing.

We’ve all seen impossible-to-understand product manuals due to terrible translations. They don’t inspire confidence in product quality and, with a high-amperage welder, can be dangerous.

Any manufacturer that isn’t responsive to your questions, or can’t provide an easy-to-read and helpful manual, doesn’t deserve your business.

If you haven’t seen it already, check out this excellent manual for the Multimatic 215. Miller and Hobart do a fantastic job with their manuals.

The big picture

For most DIY and home use, MIG welding with a metal of 1/4 inch or less, the Hobart 140 makes the best 110-volt MIG welder.

It’s simple to use and solidly built—but still portable. And thanks to a fantastic wire drive system, it’s reliable.

It’s a great choice for any garage.

My runner-up choice includes dual-voltage and spool gun capability. The affordable Hobart 210 MVP offers the most value among even the best 110-volt MIG welders. It’s a solid mid-range choice for home use that most hobbyists won’t outgrow.

If you want it all—MIG, flux core, TIG and stick—in one portable, dual-voltage unit, the Miller Multimatic 215 is the best premium 110-volt MIG welder.

It’s a fun-to-use “smart” machine that will make just about anyone a better welder.