What Size Generator for Welding?

Sometimes it’s just more practical to tackle welding jobs in the field instead of in the comfort of your shop.

Today’s generators and welders are more powerful and portable, making it easier than ever to weld at remote locations, but what size generator for welding is right for you?

Jump to:

How to Size a Generator for Welding

Because welders are complicated, and the manufacturers use different designs and components to achieve rated output levels (and even how they rate output varies), I don’t recommend that you use the amperage output rating to size a generator.

The generator doesn’t care how many amps the welder can develop. What matters is how many watts the welder consumes to create its welding amperage.

I’ll take you through the calculations, but for those in a hurry, this chart will give you a general ballpark idea of how much generator wattage you’ll need for welding.

Generator Sizing Chart for Welders

| Welder Amperage | Minimum Generator Size | Recommended Generator Size |

|---|---|---|

| Up to 100A | 3000 watts | 4500 watts |

| 120–160A | 4500 watts | 6500 watts |

| 180–200A | 6500 watts | 8000 watts |

| 210–250A | 10000 watts | 13000 watts |

I like this 6250-watt generator to power any size 120V welder, and this larger model for 240V welders up to 250A.

You’ll find generator output usually expressed in watts. Here’s the basic formula we’ll use:

Watts = Volts x Amps

For example, this tells you a generator rated at 4800 watts powering a 120-volt device supplies 40 amps of current (4800 watts = 120 volts x 40 amps), and if capable of 240-volt output, that same generator provides 20 amps (4800 watts = 240 volts x 20 amps).

Convert output rated in kVa (kilovolt-ampere) to watts by multiplying by 800. For example, a generator rated at 9 kVa multiplied by 800 converts to 7200 watts.

Look for two output ratings for a generator. One for a steady ongoing load known as the operating, or running watts.

Most generators can also handle a brief output spike that occurs when a motor (or a welder) starts. Typically 25-30% higher than the running figure, this is the start-up or surge watt rating.

Most generators include some wattage value in their model name. You’ll want to check if it represents running or surge watts, as this varies by manufacturer.

Sizing a generator to power a welder starts with knowing the maximum watts the welder will draw. Then you’ll know the minimum watts your welder needs to operate at full capability.

How Many Watts Does Your Welder Use?

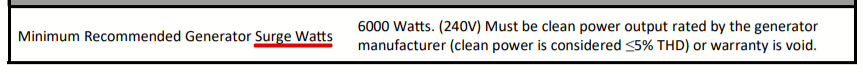

It’s rare to find total watts listed for welders, but a few manufacturers provide helpful minimum generator size recommendations.

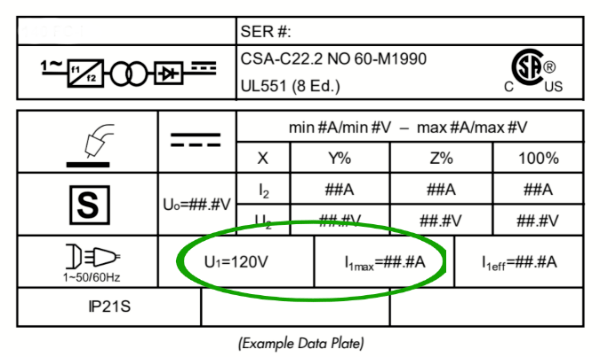

While not all manufacturers bother to provide this information, you can calculate watts using voltage and amperage figures from the owner’s manual or the data plate on the welder.

Use the Manufacturer’s Voltage Rating

While you’ll find generators rated for 120 and/or 240 volts, some manufacturers rate their welders at 110, 115, or 230 volts.

For accuracy, it’s best to use the manufacturer’s number listed as U₁ on the data plate. This is the voltage they used to rate the machine and measure amperage values.

Get the Right Amperage Value

Depending on the welder, you may find a handful of different amp ratings, or just one.

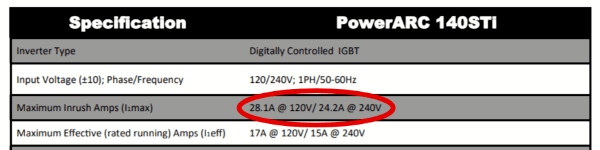

Look for the I1max number. It’s the best rating to use because it represents the maximum rated supply current. You may see this referred to as the maximum “inrush” or “surge” current draw on startup.

Multiply the I1max amperage by the manufacturer’s voltage rating to get the maximum watts required for your welding machine.

Using the welder specifications from above:

24.2 amps x 240 volts = 5808 maximum watts

The manufacturer, Everlast, recommends a minimum 6000-watt surge generator in the 140 STi owner’s manual.

The I1eff amp number is a thermal rating taking into account rated duty cycle limits (idle time) and heat buildup to size dedicated building circuits. Without adjustment, it’s too low to calculate maximum watts.

When manufacturers give both ratings, I find the I1max is normally 1.7 to 2.2 times greater than the I1eff rating.

Some data plates show just an I1 or “recommended circuit breaker” information, as on a Lincoln 140.

Using the specs Lincoln gives us:

20 amps x 120 volts = 2400 watts

But I’ve seen Lincoln representatives say this welder requires, at a minimum, a 3000-watt generator. And 3000 watts divided by 120 volts gives us 25 amps, which is likely closer to the I1max rating for this machine.

The recommended circuit breaker size may be too small to calculate full operating wattage. A properly operating circuit breaker is designed with a time delay and probably wouldn’t trip because of a brief 25 amp surge.

But this would cause a problem on a generator with a surge rating of 2400 watts.

Finally, don’t make the mistake of using output amperage figures such as I2 or duty cycle amperage.

Adjustments to Consider

Before deciding on what size generator to run your welder, here are a few more things to consider.

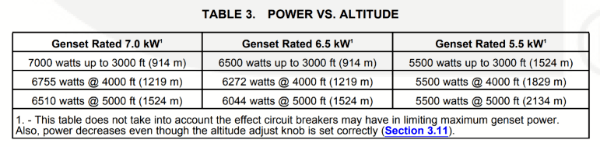

Derate for High Altitude Operation

Thinning of air means less power at greater altitudes.

According to one generator manufacturer:

“…air density decreases as altitude increases, causing rated genset engine power to decrease—approximately 3.5 percent each increase of 1000 feet (305 m) (Table 3). It may be necessary to run fewer appliances at higher altitudes.”

Cummins Onan – Generator Operator’s Manual

These Onan generators include an altitude adjustment control. High-altitude kits are available for many generator models.

Don’t Forget Accessory Equipment

You may need to operate work lights, fans, and air compressors while welding, and this adds to your total wattage requirement.

Grinders and chop saws can use up to 1800 watts each. This isn’t an issue if you’re working solo. But in a team situation, sizing the generator for twice the welder’s maximum watts will minimize the impact on your weld of other tools starting up.

Here are power requirements for common devices:

| Appliance | Running Watts | Starting Watts |

|---|---|---|

| Coffee Maker | 1750 | 0 |

| 625W Microwave | 625 | 800 |

| Single 60W equivalent CFL bulb | 15 | 0 |

| Radio | 50-200 | 0 |

| Room Air Conditioner: 10,000 BTU | 1500 | 2200 |

| Small Appliance | 200 | 1700 |

| 8in. Bench Grinder | 1400 | 2500 |

| Pressure Washer: 1 HP | 1200 | 3600 |

| 7-1/4in. Circular Saw | 1400 | 2300 |

| Electric Chain Saw: 14in. Bar, 2 HP | 1100 | 0 |

| 10in. Table Saw | 1800 | 4500 |

| Drill: 3/8in., 4 Amps | 440 | 600 |

| Drill: 1/2in., 5.4 Amps | 600 | 900 |

| Portable Heater (Kerosene, Diesel Fuel): 90,000 BTU | 500 | 725 |

| Battery Charger: 60 Amp with 250 Amp Boost | 1500/5750 | 0 |

| Laptop | 65 | 0 |

| LCD Computer Monitor | 25 | 0 |

| Inkjet Printer | 15 | 0 |

| Tablet | 12 | 0 |

| Cell Phone Charger | 10 | 0 |

“Dirty” vs. Clean Power Generators for Welders

Welder internal power sources fall into two distinct design categories, each handling incoming current in different ways to create weldable power output.

Traditional Transformer-Based Welders

With large transformers made from copper and aluminum, these heavy power sources change AC input current into low voltage/high amperage DC power for welding.

Very reliable and not sensitive to dirty power, traditional welders work well with any generator.

Inverter-Style Welders

With technology to create efficient welding power with much smaller transformers, inverter welders often weigh less than half of traditional welders. They achieve a very stable output thanks to capacitors that store high voltages.

But these sophisticated electronics need quality input power.

Many generators create excessive voltage and frequency fluctuations known as “dirty power”. It’s measured as a percentage of Total Harmonic Distortion, or THD. Dirty power can quickly destroy sensitive electronics or shorten service life with cumulative damage.

Particularly sensitive are older inverter welders using metal-oxide-semiconductor field-effect transistor (MOSFET) technology.

Newer machines based on insulated-gate bipolar transistors (IGBT) fare better, but still require a clean power generator with 5% or less THD.

Here’s a video showing a Lincoln 180 MIG welder running on a 7250-watt generator:

Generators for Welders

Compact and reliable, a modern portable generator will power your welder and other tools at any job site, and keep your lights and refrigerator on at home during power outages.

Conventional Generators for Welders

Essentially a motor-driven AC alternator, traditional general-purpose generators make power in a single step. Spinning the alternator at 3600 RPM creates 120 volts with a frequency of 60 Hz.

Any variation to this speed causes voltage and frequency to fluctuate, resulting in harmonic distortion. Sure, the governor will try to maintain a steady RPM, but any significant change in the load will cause a brief spike up or down.

While traditional transformer-based welders work well with conventional generators, the power does not meet clean standards. This style of generator should not power inverter-based welders needing 5% or less THD.

Inverter Generators for Welders

It turns out that the same inverter technology that gives welders a stable output also helps generators make clean power in three steps:

- Generate high frequency AC with an engine-driven alternator

- Convert AC to DC current

- Invert DC current into a lower and very stable AC supply current

Starting with high energy, the AC current allows the inverter more control over the final output. The result is a stable sine wave with low THD (under 5%) that is perfect for both inverter and conventional welders, along with other sensitive electronics.

Tips for Welding with a Generator

- Size the generator to your welder:

- Know your welders wattage requirement for full operation. From the data plate, multiply I1max (max amps) x U₁ (volts) = maximum watts.

- Include watts for accessory items that you might need while you weld: lights, fans, etc.

- Allow for 3.5% of power loss per every 1000 feet of altitude.

- Choose a generator capable of producing at least 25-30% more watts than you need for best results.

- Undersized generators can have larger voltage and frequency spikes. This is hard on the generator and welder. It also makes welding more difficult.

- A generator running at 50-60% capacity will handle load fluctuations better than one running at 90%+.

- Starting and Shutdown: Unplug your welder before starting or shutting down the generator.

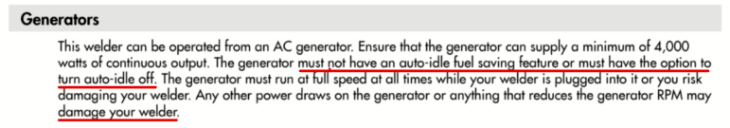

- Auto-Idle: Disable off any fuel saving feature so the generator always operates at full speed while connected to the welder.

- Fuel: Keep topped up with fresh fuel. You never want the generator to stop running while connected to the welder—especially while you’re running a bead.

- Maintenance: Keep the generator operating properly. Don’t operate your welder on a generator that isn’t running well.

- Power/Extension Cords: Don’t use cords that are undersized or in poor condition. Here’s how to size a welder extension cord.

Will a 3000 watt generator run a welder?

A 3000-watt generator with 120-volt output can generate 25 amps of current (Amps = Watts/Volts). While many 120V welders draw more amps at full power startup, a small welder with 90 to 100-amp output should work.

Will a 5000 watt generator run a welder?

Yes, a 5000-watt generator is ideal for 120V welders that draw less than 40 amps at startup, which includes most welders up to 160 amps. But most 240V machines need more than 5000 watts to run at full capacity.

What size generator to run a 140 amp welder?

Many welders rated for 140-amp output will draw less than 30 amps at startup, but some need nearly 40 amps.

To be safe, get the I1max (max amps) rating and multiply it by the voltage for the maximum watts. Expect to need 3600 to 4800 watts for full operation of a 140-amp welder.

Conclusion

Some of you are researching what size generator to use for an existing welder, and others have a generator and want to know what size of a welder it can handle.

Either way, you can now make an informed decision based on the minimum wattage required to operate a welder at full capacity.

While it’s ideal to power your welder with a generator having 30-50% more capacity than you need, you may decide that a welder/generator combo allowing only 80% of welder capacity is right for you.

You’ll make the call based on your situation. Sizing a generator for welding forces us to balance power, price, and portability.