Many in the market for a good-quality 140 amp MIG welder for home or small-business use will face a Hobart 140 vs Lincoln 140 decision.

First-time beginners wary of no-name, cheap, knock-off welders (or second-time buyers replacing one) look to trusted brands like Lincoln and Hobart.

When comparing build quality and specs, the Hobart 140 and Lincoln 140 are similar. Hobbyists choosing either will get a solid, no-frills, easy-to-use beginner welder—you almost can’t go wrong.

With experience using both welders, I’ll focus this comparison on what makes them different.

You’ll see why the Hobart 140 makes a better choice for most, and when the Lincoln 140 is the best fit.

Side by Side Comparison: Hobart 140 vs Lincoln 140

Hobart Handler 140 (#500559)

The Hobart Handler 140 enjoys a strong reputation among welding hobbyists as a dependable, user-friendly MIG welder.

It’s also versatile.

In the garage, it’s used for both flux-cored welding of heavy auto suspension parts and MIG welding the thinnest auto body sheet metal.

It’s assembled in Troy, Ohio, by the century-old welding manufacturer, Hobart Welding Products. Hobart designs its products for consumer DIY and small business users.

While sharing some components as sister companies, Hobart and Miller Electric produce welders in separate plants. Miller builds its prosumer and commercial products in Appleton, Wisconsin.

Illinois Tool Works owns both Miller Electric and Hobart brands.

Related: see the full Hobart Handler 140 Review.

- Extremely popular first MIG welder for many hobbyists

- Dependable, straightforward operation is ideal for learning to weld

- Five voltage positions (compared to Lincoln's four) for finer control of heat in the weld

- Wire feed system that's fully adjustable from 40 to 700 inches per minute for even greater arc control

- Limited use on aluminum because adding a spool gun is not an option

A Hobart 140 welder package includes:

- 10 ft. MIG gun & cable

- 10 ft. work cable with clamp

- Power cord with plug

- Built-in gas solenoid valve and dual-gauge regulator (for 100% Argon or Argon blends) with gas hose

- .030 in. contact tips

- Quick Select™ drive roll for .024 in. or .030/.035 in. solid wire, and .030/.035 in. flux-cored wire

- Sample spool of .030 in. self-shielding flux-cored wire

- Material thickness gauge

Hobart Handler 140 compared to Lincoln 140

Pros

- Wire feed system handles difficult to feed wires at up to 700 inches per minute (ipm)

- Welds aluminum (limited) without an expensive accessory

- 5-position voltage control to fine-tune heat

- Convenient 3-groove Quick Select drive roller

- Warranty covers transformer for 5 years

- Assembled in USA

Cons

- No spool gun option

- Regulator not approved for CO2 shielding gas

- Work clamp is small and not heavy-duty

2-minute Hobart Handler promo video.

Lincoln Electric Easy-MIG 140 (#K2697-1)

The Lincoln Electric Company, based in Euclid, Ohio, began manufacturing electric motors in 1895. By 1911, they developed the first variable voltage, single-operator, portable welding machine.

Now a global manufacturer, Lincoln Electric assembles its retail MIG welders in Mexico.

The Lincoln 140 is popular with do-it-yourself welders and is known as a good welder for sheet metal. It also has the power to weld 5/16-inch mild steel using flux-cored wire and multiple passes.

This comparison includes Lincoln’s consumer-grade 140-amp MIG welders. Marketed under various retail names, these share identical specifications and components.

The models, similar in appearance, except for face-plate branding, include:

- Weld-Pak® 140HD

- MIG-Pak® 140

- Easy-MIG® 140

- PRO MIG® 140

Not included in this comparison guide are the Lincoln PowerMIG® 140C and 140 MP. Learn more about Lincoln 140 MIG welders.

- A long-time favorite MIG welder of hobbyists and homeowners

- Four voltage control positions to adjust weld heat

- Fully adjustable wire feed speed of 50 to 500 inches per minute

- For easy welding on aluminum, you can connect the optional spool gun (not available for Hobart 140).

A Lincoln 140 welder kit includes:

- Magnum® 100L gun and 10 ft. cable assembly

- Work clamp and 10 ft. cable

- .025 in. and .035 in. contact tips

- Gasless nozzle for flux core welding

- Gas nozzle for MIG welding

- Spindle adapter for 8 in. diameter spools

- .025 – .035 in. wire diameter dual track drive roll for MIG and flux-cored welding

- Gas Regulator and hose for use with Ar/CO2 blend gases and 100% C02 (C02 bottle adapter sold separately).

- Sample spool of .025 in. diameter MIG wire

- Sample spool of .035 in. diameter flux-cored wire

- How to MIG Weld DVD

- Instruction manual

Lincoln 140 Compared to Hobart Handler 140

Pros

- Spool gun ready

- Heavy duty work clamp with bonding strap between jaws

- Tool-less wire spool, wire drive, and polarity changes

Cons

- Aluminum welding requires optional spool gun

- No longer assembled in USA

- Warranty

- Only 4 voltage settings

Lincoln’s 2-minute Easy MIG 140 promo video.

Hobart 140 vs Lincoln 140: What’s different?

Because the welders are close in specifications and function, let’s focus on what makes the Hobart 140 and Lincoln 140 welders different.

Controls

You’ll find little difference in operating either welder.

Both machines provide a simple control panel with an on/off switch and two knobs for voltage and wire feed speed (WFS) changes.

The rocker-style power switches are glove-friendly. The control knobs are small, but usable while wearing welding gloves.

Voltage

A 5-position voltage control adjusts heat on the Hobart 140. The Lincoln 140 uses a similar control, but with only 4 heat levels.

With fixed, or “stepped” settings, voltage can’t be used to fine-tune the welding arc, so you must rely on WFS adjustments.

With an extra position, the Hobart welder gets you closer to an ideal heat setting so there’s less need to fine-tune wire speed.

Wire Feed Speed

While weld parameter charts are generally accurate, ideal wire speed varies because of stick out, travel speed, weld angle, cleanliness of metal, etc. The settings are “in the ballpark” so it’s normal to make small changes to WFS for the best arc.

Each welder provides infinite control of WFS within its range. However, the Handler 140’s range is significantly wider, 40 to 700 IPM, when compared to the Easy-MIG’s 50 to 500 IPM.

While it uses the highest speed only for aluminum work, the extended range of the Hobart 140 gives you more flexibility.

When dialed in correctly, I found no difference in the arc or weld quality between the Hobart 140 and Lincoln 140.

The Hobart Handler 140, when compared to the Lincoln 140, provides better overall control of welder settings. You’ll find this useful to fine-tune your weld, whether on the thinnest gauges or thicker metal.

Components

Wire Drives

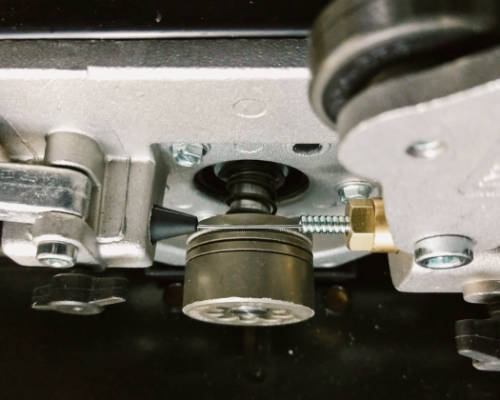

Both manufacturers equip their welder with a reliable cast aluminum wire drive. Each features a calibrated tension control and tool-less drive roll changes.

The Lincoln MIG welder uses a smooth dual-groove roller. One groove handles .025″ solid wire and the other .030/.035″ solid or flux core wire. It’s an easy tool-less change but requires removing the drive roll to flip it around.

The Hobart Quick Select system is better thought out. It features a user-friendly triple-groove drive roller. Wire changes are faster on the Hobart 140: push-in, twist to align pin with wire type, and then release. All three grooves are available without removing the roller.

You get two smooth grooves for .024” solid wire and .030/.035” solid or flux core wire. The extra .030/.035” knurled groove provides a good grip on soft wire allowing the use of lighter roller tension settings. This helps avoid wire feed issues caused by squeezing or deforming.

Hobart’s wire drive system is so good that they rate the Hobart Handler 140 to weld aluminum of 12- to 16-gauge.

There’s a reason most manufacturers don’t make this recommendation.

That’s because their wire drive systems cannot push soft aluminum wire at high speed through a long cable and gun without birdnesting, crushing, or jamming the wire.

But the Hobart 140 is up to this task. I became a big fan of the Hobart MIG welder and its wire drive system—despite owning a Lincoln 140 that I still think is great—after testing it on aluminum.

See the exact settings I used to MIG weld 1/8-inch aluminum without a spool gun.

Both the Lincoln and Hobart machines have strong, reliable wire feed systems. Either way, expect a trouble-free welding experience. But the Hobart is easier to use, has more range of adjustment, and allows light-duty aluminum work without an expensive accessory.

Gas Regulator/Gauge Set

Included with each welder is a good-quality brass regulator with hose and dual gauges.

You’ll use the dial marked in CFH (cubic feet/hour) to adjust and monitor gas flow. The second dial displays the gas cylinder pressure in pounds per square inch (PSI). This shows the remaining gas volume.

The Harris regulator is included with the Lincoln 140, and the Miller-branded Hobart regulator work with 100% Argon and Argon blends, such as C25 MIG-mix.

Lincoln’s regulator also works with less expensive 100% C02 gas. C02 tanks have a different fitting than Argon, but a simple adapter solves that. Hobart (Miller) doesn’t approve the use of 100% C02 gas with their regulator.

Gun/Cables

Both welders include 10-foot MIG guns and work cables. The guns are comfortable to use and a quality covering makes the cables easy to handle.

Ground cables are both heavy 6-gauge, but Hobart skimped on the work clamp. It’s smaller and lacks a bonding cable.

The heavy, braided wire in the Lincoln 140 clamp bonds the jaws together. It makes a good circuit even when the bottom jaw has better contact with the work material. This is because the current travels through the bonding cable instead of the hinge or spring.

While I haven’t had an issue while using the Hobart 140—other than its small size—I always make sure the top jaw has solid contact. Fortunately, replacement with a good clamp is a cheap and easy fix.

With the Lincoln 140, you get a true heavy-duty clamp.

Overload Protection

Lincoln and Hobart designed three levels of protection into their 140-amp welders.

- Wire Drive Motor Protection – Both machines protect their wire drive motors with a separate automatic overload circuit.

- Output Overload – Each includes a manually resettable circuit breaker to protect the welder from exceeding maximum output.

- Thermal Protection – An automatic thermostat protects the power transformer from overheating when you exceed the duty cycle. It prevents further welding until the fan cools the unit.

Manufacturers provide duty cycle ratings to show how long a welder can operate at a certain power output level.

Both our welders have a typical 110V MIG welder duty cycle rating of 20% @ 90A. This tells you that when producing 90 amps of output, they should operate for a maximum of 2 minutes (20%), and rest (cool down) for 8 minutes, during a ten-minute period.

This rating is about 2/3 power for a 140-amp welder. Duty cycles vary inversely with output power. Increasing the output will reduce the duty cycle while decreasing output will increase the duty cycle.

Exceeding the duty cycle could overheat the machine, causing the thermal overload relay to trip. The welder stops welding, but the cooling fan runs until the excess heat dissipates.

The advantage goes to the Hobart 140 for providing an indicator light on the front panel to show an over-temperature condition. This illuminates while the machine is in thermal protection mode and turns off when ready to weld.

With the Lincoln welder, you don’t get an overload confirmation and don’t know if it’s ready until you pull the trigger.

Owner’s Manual

A complete, well-written, and illustrated user’s manual reflects a manufacturer’s commitment to customer satisfaction.

Hobart includes a handy copy of the weld settings chart found on the welder. Lincoln’s manual lacks this important resource—but is otherwise complete.

I just find Hobart manuals more user-friendly. See what you think:

View the Lincoln Easy MIG 140 Owner’s Manual

View the Hobart Handler 140 Owner’s Manual

Welding Aluminum

What plans you have for welding aluminum might be the deciding factor between these welders.

Lincoln 140 is designed with spool gun capability for trouble-free welding of 22- to 10-gauge aluminum. (Lincoln Electric K2532-1 sold separately)

This gun’s short feed distance eliminates feed issues common with soft aluminum wire, such as bird-nesting.

This accessory isn’t an option with the Hobart Handler 140. However, the Hobart can weld aluminum of 16- to 12-gauge on its own—just not as easy.

When comparing Hobart vs Lincoln, the Lincoln 140 is the better welder for aluminum work.

Warranties

Still on the fence?

The big warranty difference might be your tipping point.

Lincoln’s 3-year parts and labor warranty protects the Lincoln 140 series welder. Exclusions to this warranty apply to the MIG gun (90 days) and gas regulator (one year). No coverage for wear and tear on cables.

The Hobart 5/3/1 warranty features parts and labor coverage to five years on the power source (transformer), three years on the drive system, control boards, and regulator. They cover the MIG gun, contactors, and relays for one year (90 days for industrial use).

While Lincoln provides solid coverage, the warranty advantage goes to Hobart.

The Bottom Line

In a recent article, the Hobart Handler 140 topped the list of best 110-volt MIG welders.

It’s also the best choice in this Hobart 140 vs Lincoln 140 comparison—when aluminum projects are not a priority.

Both welders are portable, dependable, and easy to use—even for beginners. But the Hobart 140 is more user-friendly, has a better wire drive (the heart of a welder), and a stronger warranty than the Lincoln 140.

On top of that, Hobart continues to build its welders in Troy, Ohio, USA—not in Mexico.

Now, if you frequently weld thin aluminum—and absolutely know you will never work on anything over 10-gauge—then the Lincoln 140 is a solid choice.

But if the aluminum capability is important to you, the Hobart 210 MVP is spool gun ready and good up to 1/4-inch. It runs on 110V or 230V power.